Centerless grinding

Centreless is a process used to grind cylindrical parts with a high precision finish.

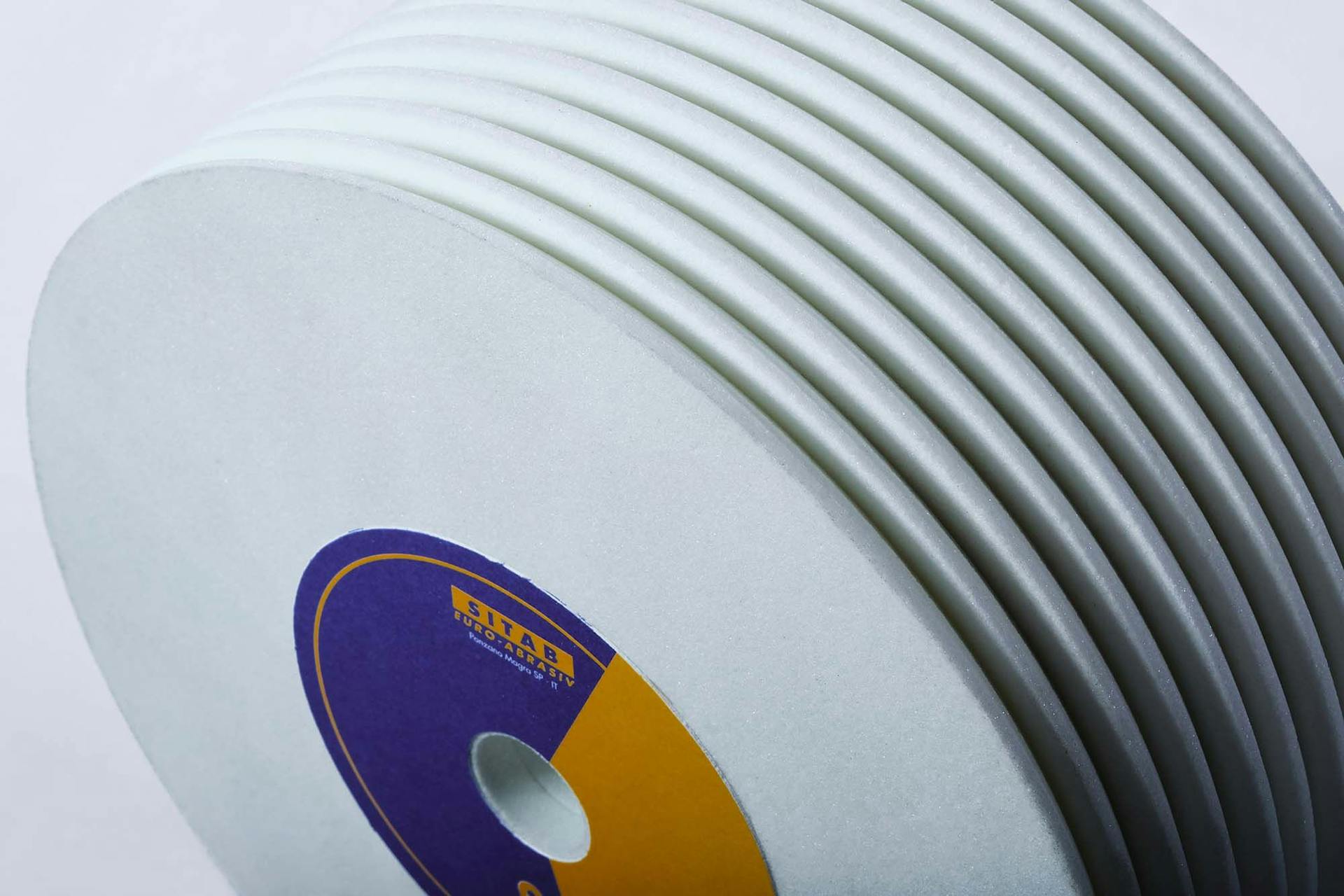

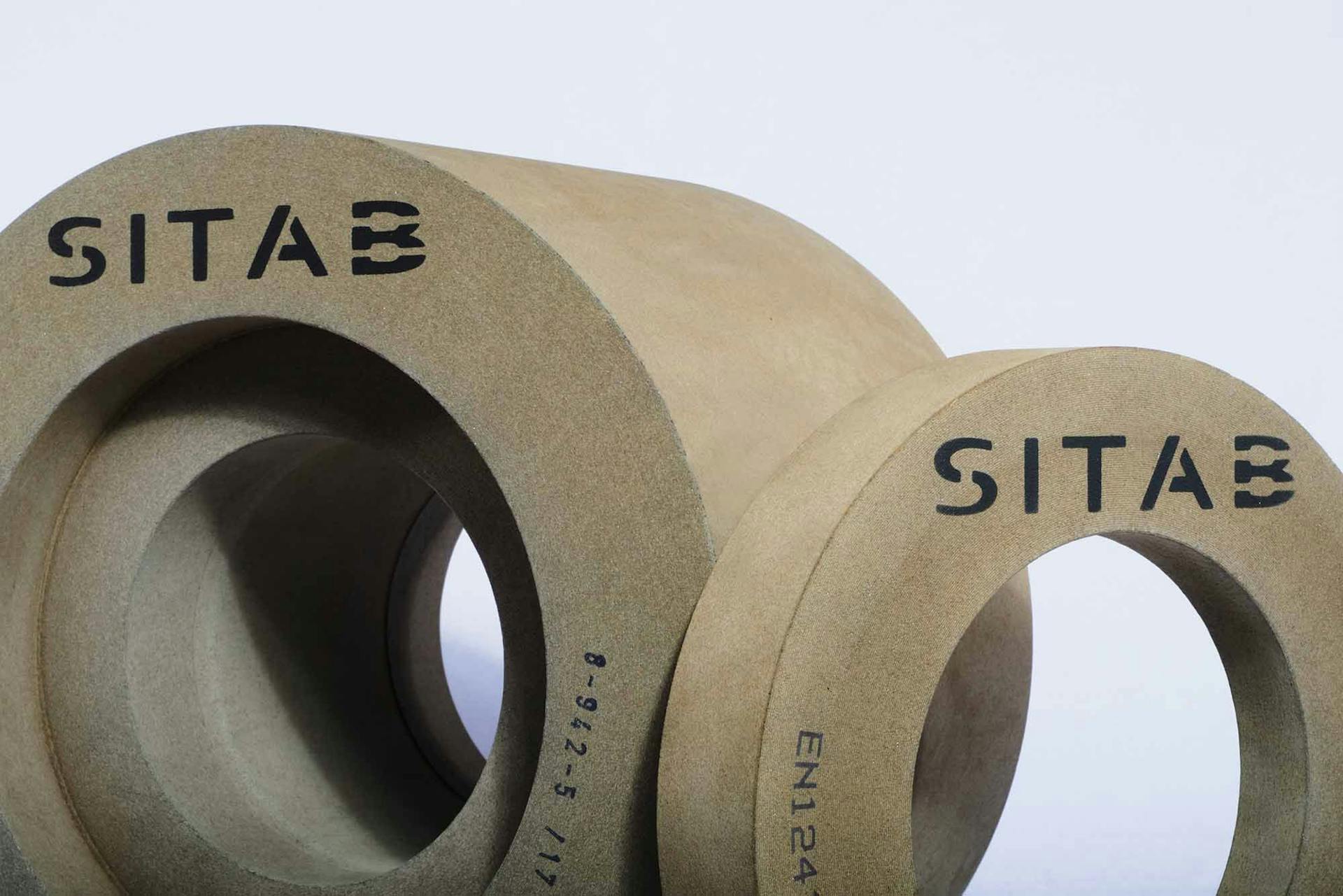

For Centreless grinding operations, SITAB is able to supply wheels with vitrified or resin bond, whether it is a plunge or a throughfeed operation.

The cutting capacity of the grinding wheel is optimized thanks to the development of special formulations that allows the best use of the properties of the abrasives.

The company can supply grinding wheels and regulating wheels for grinding of bars, small cylindrical parts, rollers for bearings and all cylindrical parts.

APPLICATION FOR CENTRELESS GRINDING

Our technicians, specialized in precision grinding processes, can design "custom made" solutions that are able to optimize production processes and reduce cycle costs.

WHEEL DIMENSIONS

- From diameter 300 to diameter 760

- Maximum thickness in single piece 355 mm on ø610 and 508

CENTRELSS GRINDING

- Plunge operation with wheels in ceramic bond or resin bond up to 63 m/s

- Throughfeed operation with wheels in ceramic bond or resin bond up to 50 m/s

For machines like

- Danobat

- Lidkoeping

- Mikrosa

- Cincinnati

- Monzesi

- Schumag

- Landgraf

- Ghiringhelli

- Junker

- Estarta